Discussion with our Leaders

Discover the advantages of prioritizing technology in your business. Gain a competitive edge in the…

December 1, 2023

As businesses strive to measure and track their performance, Key Performance Indicators (KPIs) have…

November 17, 2023

KPIs and OKRs can collaborate effectively to enhance the monitoring of business progress, growth,…

November 14, 2023

Analyse customer reviews and learn the crucial distinction between quantitative & qualitative…

November 2, 2023

When it comes to hiring for your project, there are so many options available. Find out why…

October 13, 2023

Looking for a marketing agency to help grow your SaaS product? We'll show you how to choose the…

October 12, 2023

Exploring Potential of Data & Analytics

10 Types of Power BI Dashboards for Every Industry!

Explore the different types of Power BI dashboards and learn how to transform your data into smart…

Know Your Manufacturing Insights with Power BI Dashboard

Unlike other industries, manufacturing industries are always searching for innovative ways to…

Integrating AI In Power BI: Know Why 44% Companies Trust AI for Better Decision-Making

Power BI and AI: the perfect duo! Learn how integrating AI within Power BI can transform your…

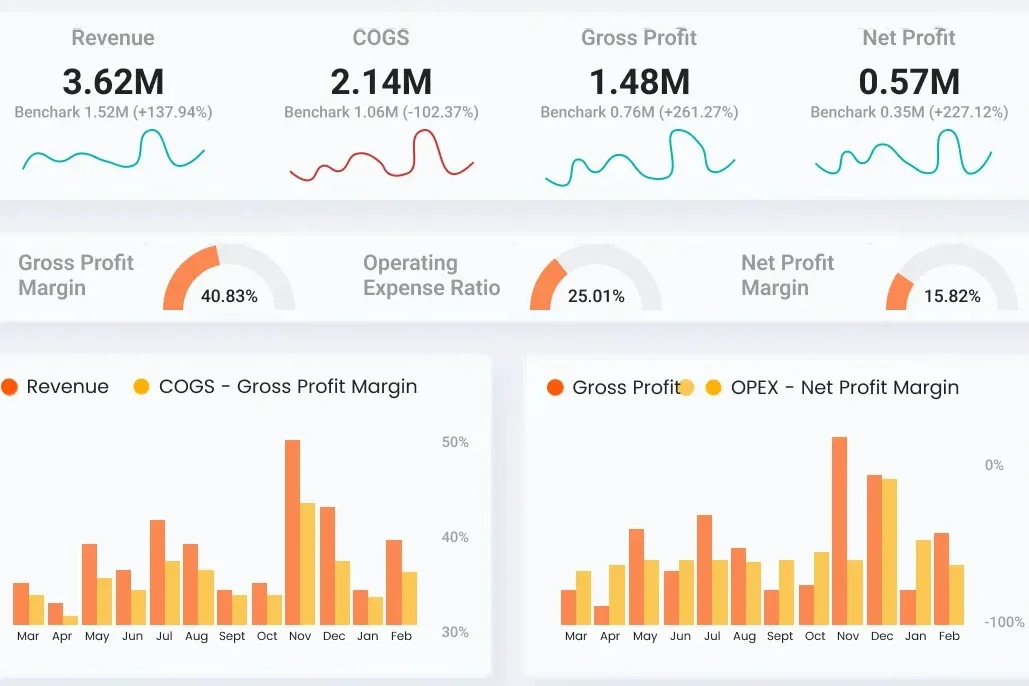

Power BI Experts & Dynamic Dashboards: Decrypting AMOT’s Business Success Story

Discover how AMOT, a top manufacturing company, transformed raw financial data into actionable…

Power BI Financial Dashboards for Optimal Fiscal Management

Power BI Financial Dashboard will uplift your financial story by providing your team with intuitive…

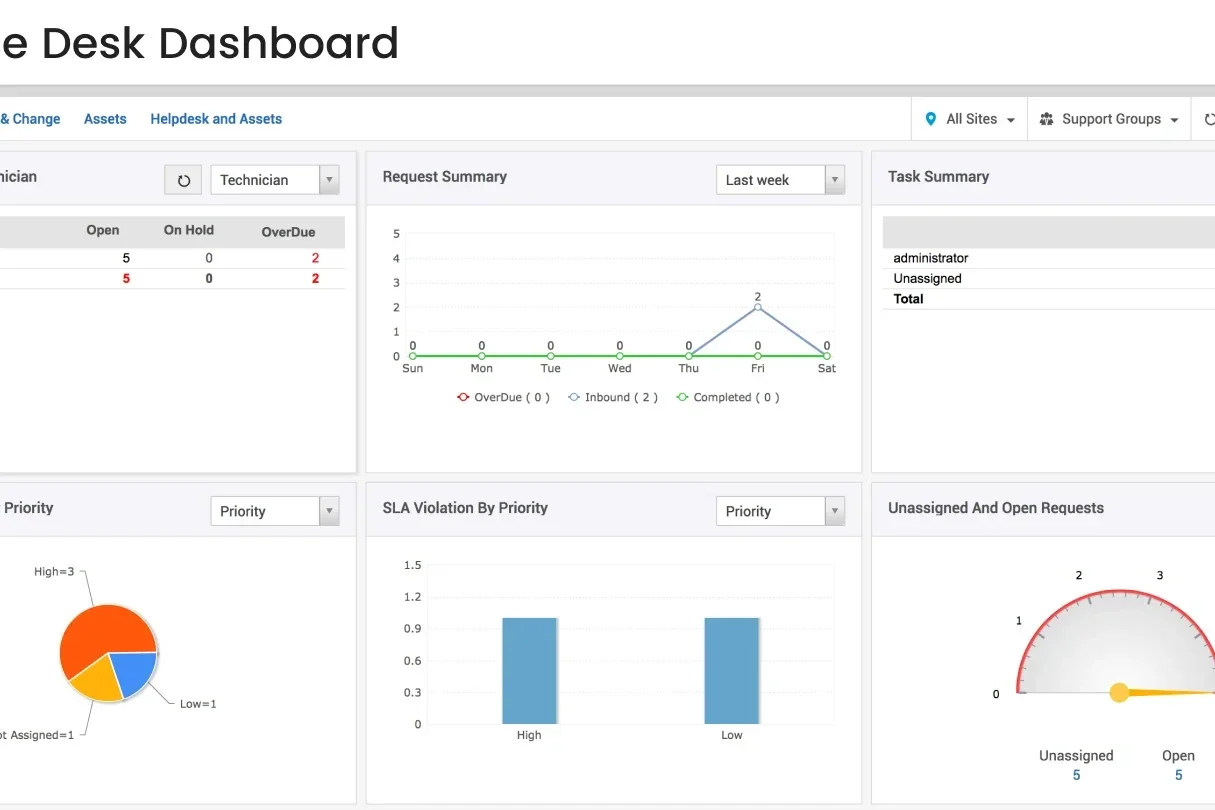

Power BI Service Desk Dashboard: The Next Level of IT Support

Power BI Service Desk Dashboard offers deep insights for best customer service. Explore how this…

Exploring AI and Machine Learning

Automating Patient Appointment Scheduling with AI and RPA

Patient Appointment Scheduling to automate healthcare workflows using RPA to prioritize resource…

Integrating AI In Power BI: Know Why 44% Companies Trust AI for Better Decision-Making

Power BI and AI: the perfect duo! Learn how integrating AI within Power BI can transform your…

Embrace the Future of Label Designing with AI: A Comprehensive Guide

Discover how AI/ML is revolutionizing the label industry. Learn how intelligent machines are…

Transforming Healthcare with AI & Chatbot

Eliminate administrative obstacles and create a more efficient and effective healthcare database…

LLMs vs SLMs

Discover the essential differences between small & large language models with Google. Learn the…

Choosing the right Chatbot Assistant for your Business

Chatbot Assistant in your business to promote efficiency, productivity and cost-reduction by…

A Guide to Digital Products

6 Signs Your Software Development Company is Cutting Corners

You are checking out the various options as you zero down on a software development company in New…

Get Your Mobile Application Feedback Heard & Seen With the New Feedback Widget

Discover the advantages of Flutter's feedback widget for app developers. Easily collect feedback…

How to Turn Your Idea Into a SaaS Business — Best Practices Guide for Creating a SaaS Product

Groove Competition has come a long way since it started in 2011. In fact, it’s hard to believe…

Nurturing Growth: A Snapshot of Sunflower Lab in 2023

As 2023 marks its closure, we had an exciting year where we learned, expanded, grew, and took away…

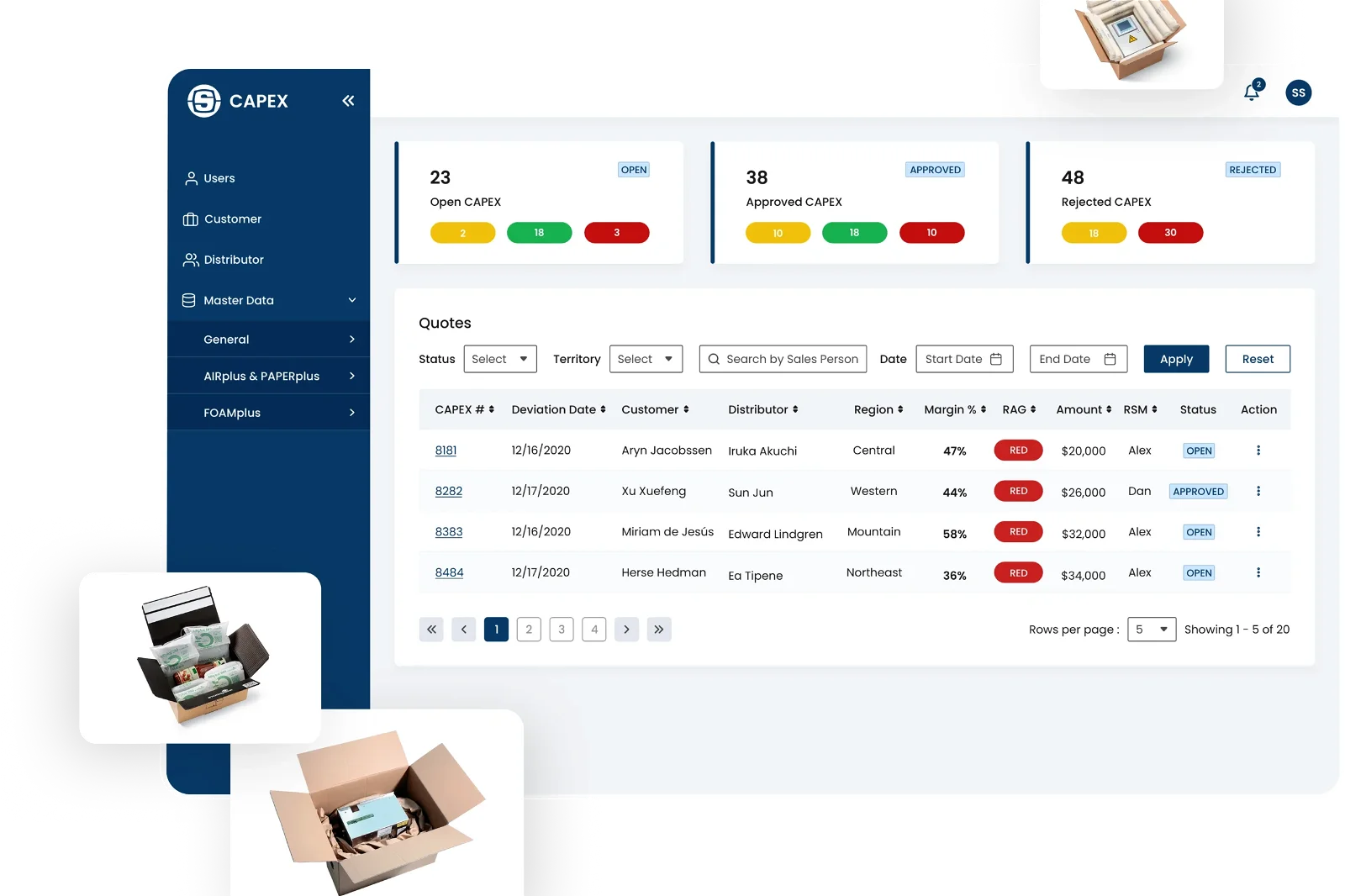

How AI/ML can Improve Automation for Quotation Process?

Quotation Automation by extracting data from email, post, or calls with Sunflower Lab’s Intelligent…

Master Power BI Report Development

Discover the power of BI reporting, analytics, and data visualization with expert techniques of…

Enhance Business Operations with Power Portal and Power Pages

Benefit from Power Portal and Power Pages to help your business using external facing websites and…

AI & Business Analytics: A Smart Guide

Know how data analytics help business & evolution of AI have paved road for digital future of all…

Azure Synapse Analytics

Learn why you must implement Azure Synapse Analytics for an upgraded Data Lake and Business Data…

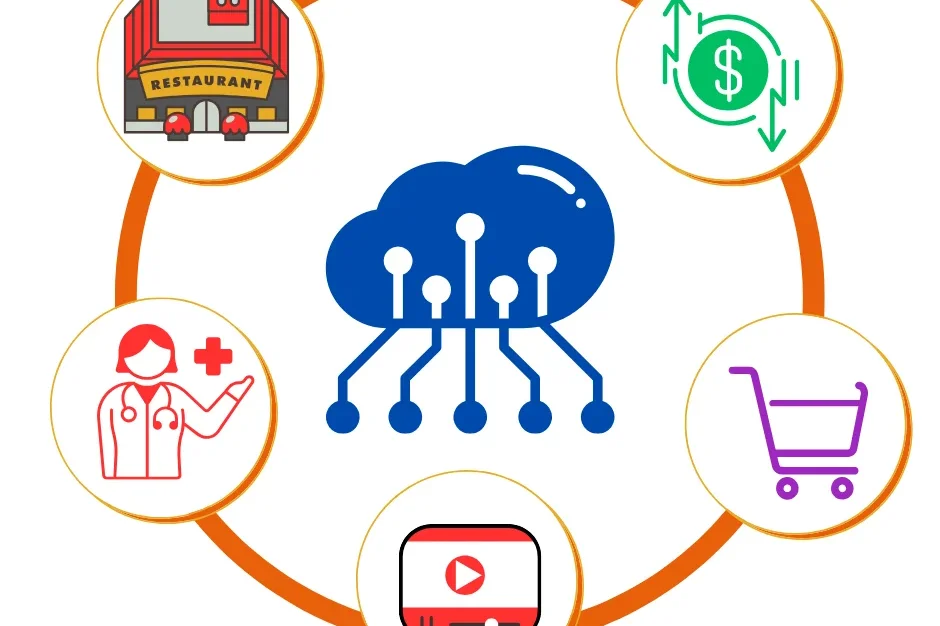

Data Lake Solutions for Industries

All leading industries can take advantage of the data lake solutions as data lake architecture…

Mastering DAX for Power BI Development

Achieve Advanced Analysis with DAX in Power BI and make data-driven decisions based on calculated…

OpenAI Launches ChatGPT Enterprise: Innovative AI Chatbot Solution for Business

OpenAI has released the most innovative, AI-powered chatbot solution. Discover what’s new with…

Let's Talk Automation

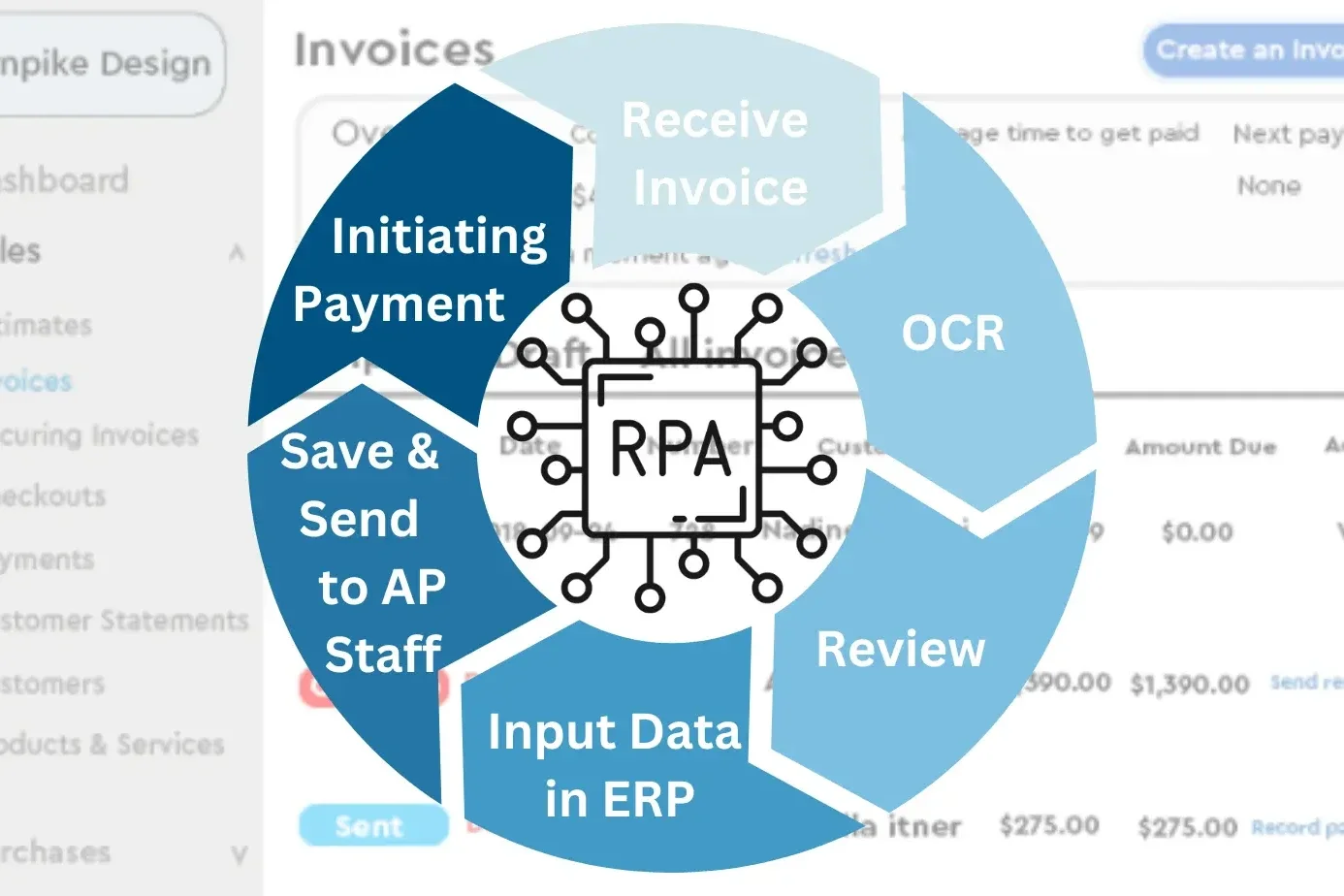

How Automating Accounts Payable can Improve Business Productivity?

AI & RPA to automate invoices that can deliver a fast & efficient Account payable workflow…

Improve Business Operations with Power Portal and Power Pages

Benefit from Power Portal and Power Pages to help your business using external facing websites and…

Why Organizations Need an RPA Strategy

Having an RPA strategy will help you avoid wasting time, clearly define your goals, and scale…

How to Calculate ROI for RPA

RPA can help your business increase innovation and productivity while decrease time and money…

How Power Apps and Power Automate Improve your Business Processes?

Empower your business with Power Apps and Power Automate – Microsoft’s low code platform and…

Enrich Employee Onboarding Process with Automated Email Data Extraction and Entry

When a new employee joins an organization, the Human Resources department must gather several…

Clock In/Clock Out App to Never Lose Track of Employee Hours Again

Clock in/Cloud Out App to increase the accuracy of payroll process, save cost & help your employees…

How AI streamlined Insurance Eligibility Verification in Healthcare

Insurance Eligibility Verification (VOB) to improve healthcare industry using automation and…

Azure Logic Apps vs Power Automate

Organizations looking for automation in this era of business technologies should decide wisely…

24/7 customer support without hiring additional staff

Market monopoly is a myth except for the very rare lucky few. For the rest of us, reducing the time…

Return 15% of Workday Back To Employees by Automating Patient Letter Process

Employee expense receipt management is the perfect process for RPA because it is logic based and…

Eliminate EHR Fatigue, Speed Up Claims Workflow with Process Automation for Medical Billers

In this process automation example, we demonstrate how RPA can be used to automate the process of…

Showcasing Our SFL Journey

Nurturing Growth: A Snapshot of Sunflower Lab in 2023

As 2023 marks its closure, we had an exciting year where we learned, expanded, grew, and took away…

Sunflower Lab INC 5000 Honoree

Sunflower achieved impressive recognition as a member of the Inc. 5000 and also secured the…

Sunflower Lab Honored at the 2023 Columbus Inno BizTech Fire Awards

Join us in our journey towards innovation and celebrate our recognition as one of the Honorees in…

Zinniax : The Excellence Award Winner

Employee expense receipt management is the perfect process for RPA because it is logic based and…

How to Communicate Within a Remote Team Members

Employee expense receipt management is the perfect process for RPA because it is logic based and…

26th Annual Webby Awards Honoring the Best of Internet

Employee expense receipt management is the perfect process for RPA because it is logic based and…

From Ideation To Support, We Partner With You All The Way

Contact our team of experts today!